Modern electronic devices not only require increasingly stringent controls over wafer geometry in terms of flatness, specimen parallelism and thickness, but also demand a very high quality surface finish on the sample as preparation for subsequent processes.

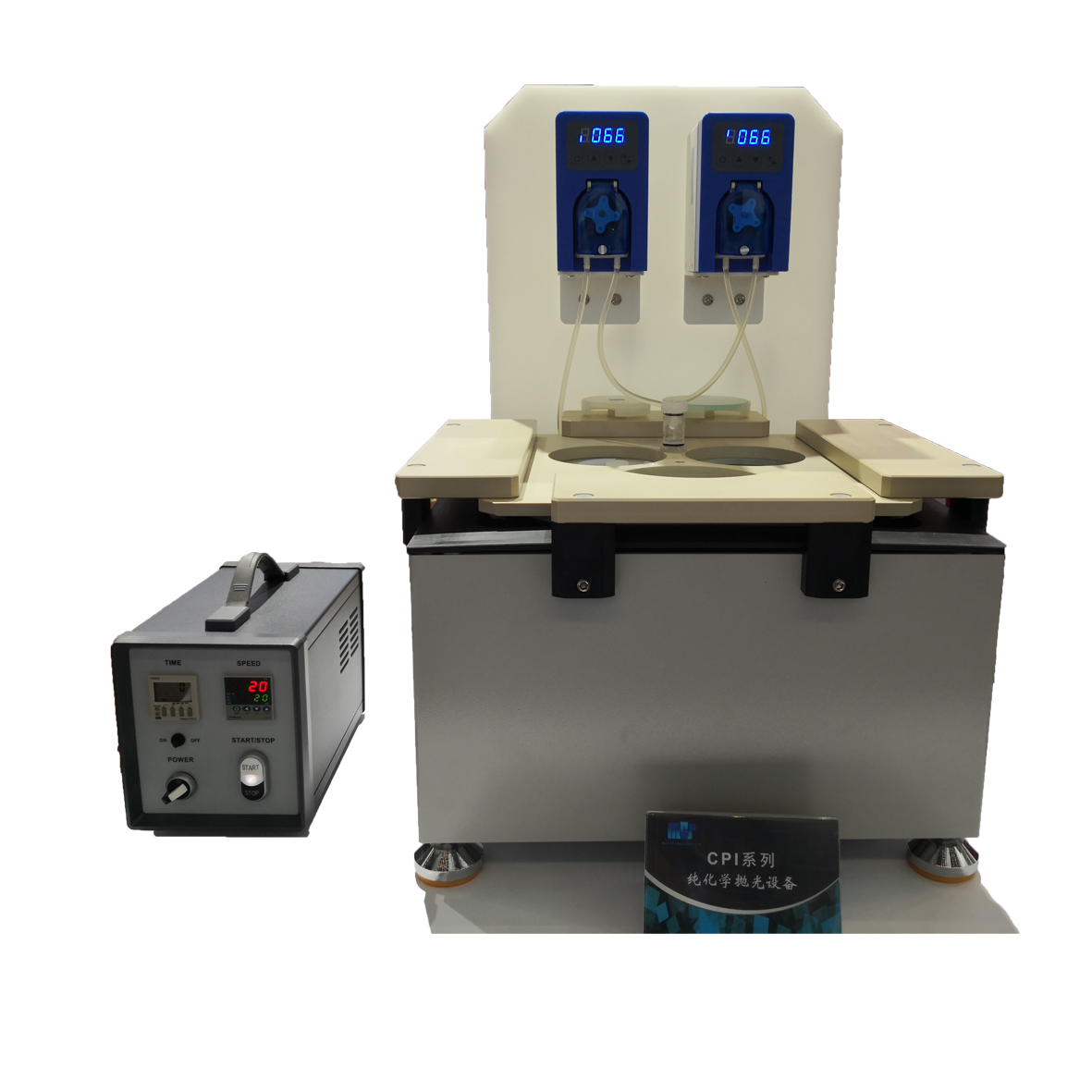

In order to achieve this aim, MCF has developed advanced chemical polishing machine as a finishing process for a wide range of materials. The systems achieve excellent surface polish with minimal surface and sub-surface damage to the crystal lattice structure.

These systems are resistant to the chemicals used in polishing processes using Bromine Methanol, Peroxide Alkaline or acid etches for example.

● Corrosion resistant construction from Polypropylene, PVDF and epoxy painted polyurethane.

● Adaptable deck arrangements to accommodate varying sample sizes and geometrics.

● Careful attention to safety aspects and operator convenience.

● Suitability for most types of aggressive etching agents (e.g. Bromine Methanol)

Technical data

Minimal subsurface damage

Wide range of wafer sizes can be polished, 3×3"、3×4"、2×3"and 1×4".

Fine etch polishing of semiconductor wafers and electro-optic crystals.